I am a metallurgical engineer, my statement of the ductile-to-brittle transition is correct. HE causes a different failure, usually a very short period (like 72 hours after put under load). The problem was not hydrogen embrittlement. Normally, the Permanente yard took an average of about 50 days to build a Liberty ship. The record speed of the construction was a propaganda effort intended to show that the United States could produce ships faster than they could be sunk.

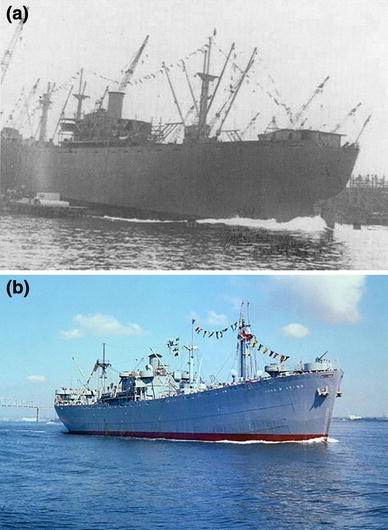

It was delivered for service on November 15, setting an additional record of 7 days, 14 hours and 32 minutes from laying the keel to delivery. Byrnes, the wife of the head of Roosevelt's Economic Stabilization Office, christened the ship and it was sent down the slipway into San Francisco Bay. She was launched at 3:27 pm on November 12 after around 250,000 individual parts weighing 14,000,000 lb (6,400,000 kg) had been assembled. During the final day the wiring, welding and painting was completed along with the installation of the forward gun platform and the inner stack. The masts, derricks and superstructure were installed on the third day. The upper deck was completed on the second day, with the installation of the lower forepeak, more bulkheads and the fantail. The boilers were put in place by mid-morning, followed by transverse bulkheads and the shaft tunnel. The bottom shell unit was installed first, followed by the inner-bottom unit to support the boiler, engine and pump. The rest of the ship was built from prefabricated 250-ton sections with the engines already in place. The keel was laid at 12:01 am on November 8, 1942. 2 Yard and pre-positioned the sections to enable the workers to assemble it with maximum efficiency. To meet the deadline, the Richmond Shipyard prefabricated as much of the vessel as possible at its No.

0 kommentar(er)

0 kommentar(er)